Introduction

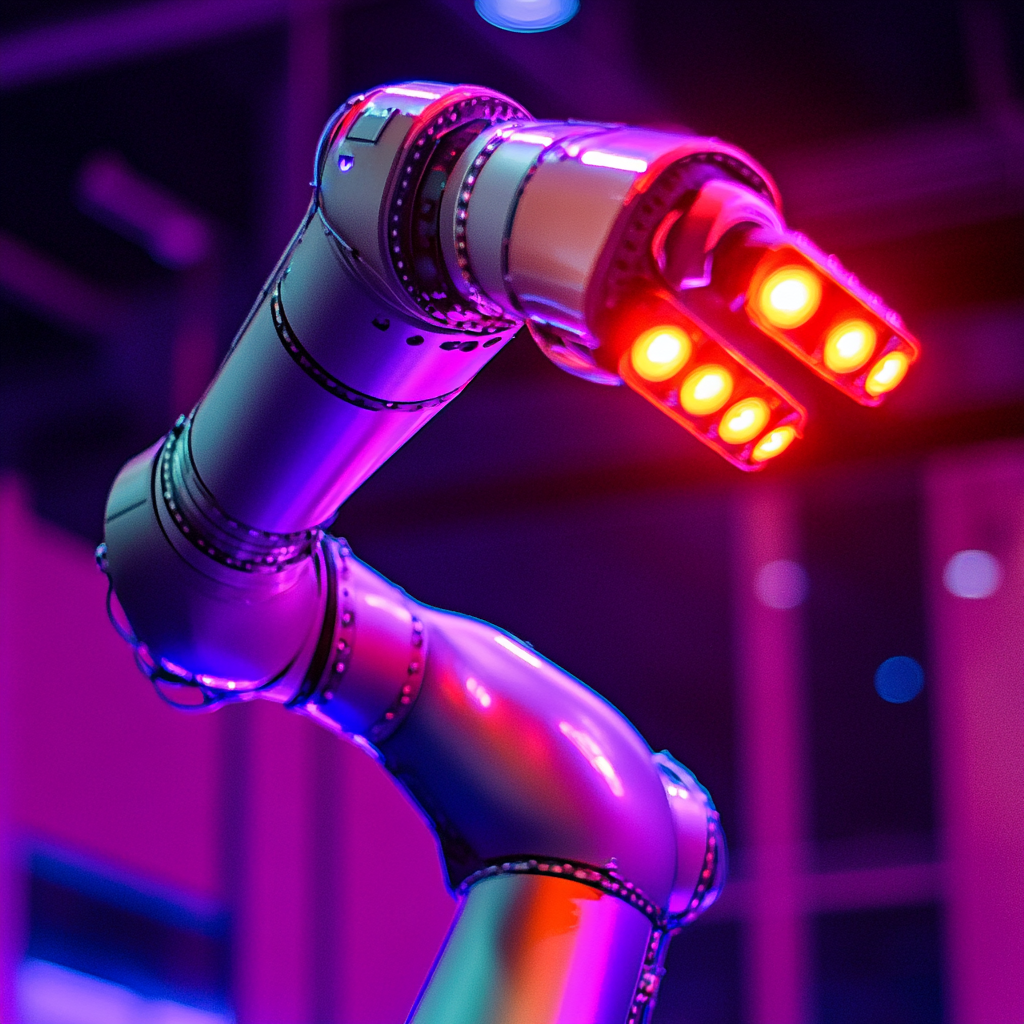

Robotic arms are vital in various industrial applications, providing precision, speed, and efficiency that are difficult for human workers to match. These mechanical devices mimic the motion of human arms and are equipped with multiple joints and actuators, enabling them to perform a range of tasks, from simple pick-and-place operations to complex assembly and welding. This blog will delve into the main types of robotic arms used in industries today, highlighting their unique characteristics, advantages, and common applications.

What is a Robotic Arm?

A robotic arm is a type of mechanical manipulator that replicates the movements and functions of a human arm. It is typically composed of joints, links, actuators, and an end effector. The end effector is the tool attached at the end of the arm, which performs tasks like gripping, welding, or painting. Robotic arms are often defined by their “degrees of freedom,” which describe the range of movements the arm can achieve, allowing it to reach specific points in three-dimensional space.

The flexibility of robotic arms makes them suitable for a broad array of applications in industries such as automotive manufacturing, healthcare, and electronics assembly. Let’s explore the primary types of robotic arms commonly used in industrial settings.

Main Types of Robotic Arms

- Cartesian Robotic Arm: Cartesian robotic arms, also known as gantry robots, operate using three linear axes that correspond to the X, Y, and Z coordinates. This design makes them particularly suitable for tasks that require precise linear movements, such as CNC machining, 3D printing, and pick-and-place operations. They are relatively simple in structure and are often used when high precision and straightforward motion paths are necessary.

- Cylindrical Robotic Arm: Cylindrical robotic arms operate along a cylindrical coordinate system, combining linear and rotary movements. These arms are ideal for tasks that require a repetitive, circular motion within a cylindrical space, such as assembly, material handling, and spot welding. The design allows for efficient use of space and easy integration into existing production lines.

- Spherical (Polar) Robotic Arm: Spherical or polar robotic arms have a combination of rotary and linear joints that allow movement within a spherical coordinate system. These arms can reach a wide area around them, making them well-suited for applications like die casting, welding, and machine loading. Their ability to handle large, awkward-shaped items with precision makes them a staple in heavy manufacturing industries.

- SCARA (Selective Compliance Articulated Robot Arm: SCARA robots are designed for tasks that require a high degree of accuracy and speed in a horizontal plane. They feature two parallel rotary joints that provide a selective compliance, allowing flexibility in the horizontal direction but rigidity in the vertical axis. This makes SCARA robots perfect for assembly tasks, pick-and-place operations, and packaging, especially in electronics and automotive industries.

- Articulated Robotic Arm: Articulated robotic arms are the most versatile type, featuring three or more rotary joints. These arms closely mimic the range of motion of a human arm, making them highly adaptable for tasks like assembly, welding, and material handling. They are widely used in industries that require complex motions, such as automotive assembly lines and heavy machinery operations.

- Parallel Robotic Arm: Parallel robotic arms consist of multiple limbs working together to control a central platform or end effector. These arms are known for their speed, precision, and load-bearing capabilities, making them ideal for tasks like flight simulators, medical surgery platforms, and high-speed pick-and-place operations. They are particularly valued in applications where stability and control are critical.

Applications of Robotic Arms

Robotic arms are used across various industries for a wide range of tasks:

- Manufacturing and Assembly: Robotic arms are essential in automotive and electronics manufacturing, where they handle tasks such as welding, screwing, and assembling small components with high precision.

- Material Handling: In logistics and warehousing, robotic arms facilitate the movement of products, increasing efficiency and reducing human labor costs.

- Medical Applications: Robotic arms assist in surgeries, laboratory automation, and the precise assembly of medical devices, providing accuracy that surpasses human capability.

- Food and Beverage: In food processing, robotic arms handle packaging, sorting, and inspection tasks, ensuring hygiene and speed.

Conclusion

Robotic arms have revolutionized industries by enhancing productivity, precision, and safety. Understanding the different types of robotic arms and their specific capabilities allows companies to select the right robot for their needs, ultimately driving efficiency and innovation in their processes. As technology advances, we can expect robotic arms to become even more sophisticated, further pushing the boundaries of what automation can achieve.

For further details on the latest advancements in robotic arms and their applications, check out the sources and explore how these technologies are shaping the future of industry.