Hello! Today’s blog post will focus on robots in the automotive industry. The automotive industry has been at the forefront of developments in automation and robotics since the late 20th century. This change is revolutionizing the industry, leading to faster, more efficient and safer processes on production lines and in assembly plants. Robots are used in a variety of tasks such as welding, painting, assembly, handling and inspection, optimizing production processes, improving product quality and reducing costs.

Use of Robots in the Automotive Industry

Welding: Robots are used to weld body panels and other components in a precise and repeatable way. This reduces welding errors and waste. Robots can perform complex welding processes faster and more precisely than human operators. This ensures consistency and quality across production lines.

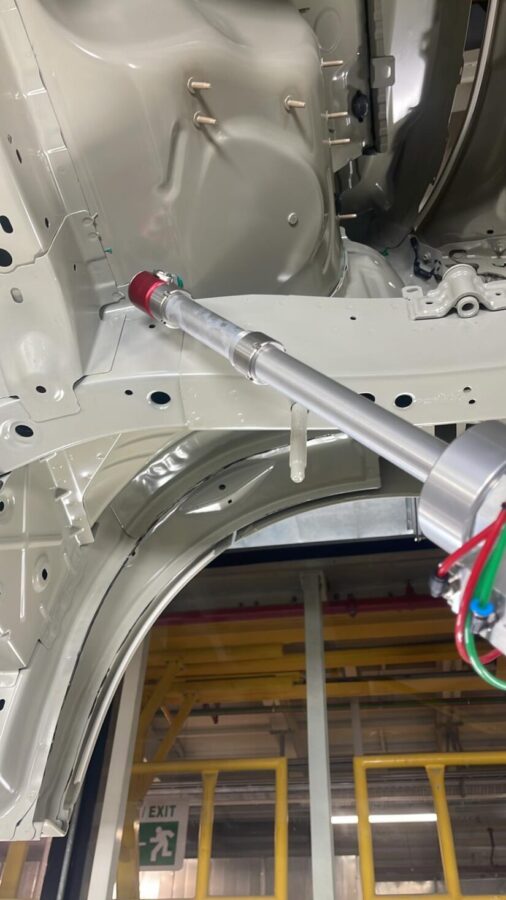

Painting: Robots are used to paint the bodies and other parts of automobiles. This helps to reduce paint wastage and waste. Robots precisely control the spray gun, ensuring a smooth and flawless finish. This reduces paint costs and improves product aesthetics.

Assembly: Robots are used to assemble various parts, including motors, transmissions and other complex components. This ensures consistency and quality across production lines. Robots can perform repetitive and tedious assembly processes faster and more reliably than human operators. This reduces labor costs and improves safety in the workplace.

Transportation: Robots are used to move parts from one station to another on the production line. This eliminates the need for manual handling and improves workplace safety. Robots can move heavy and bulky parts more safely and efficiently than human operators. This saves time on production lines and reduces labor costs.

Inspection: Inspection Robots are used to control the quality of products on production lines. This helps to reduce defects and improve product quality. Using visual perception and machine learning technologies, robots can detect product defects faster and more accurately than human operators. This reduces the risk of product recalls and increases customer satisfaction.

The Impact of Robots on the Automotive Industry

The use of robots in the automotive industry will have a significant impact at all stages, from production to sales. Let’s examine this impact in more detail:

Production

Faster Production: Robots can speed up the production process by working 24/7 and performing tasks at speeds that human operators cannot.

Lower Error Rate: Robots can dramatically reduce defects and waste due to human error because they can make precise and repeatable movements.

More Flexible Production: Robots can be easily programmed to produce different product models and variants, making production lines more flexible.

Quality Control

Improved Product Quality: Using technologies such as visual sensing and machine learning, robots can detect product defects faster and more accurately than human operators. This can lead to a significant increase in product quality.

Fewer Product Recalls: The precise quality control provided by robots can significantly reduce product defects and the risk of recalls.

Logistics and Storage

More Efficient Warehousing: Autonomous robots can be used to store and transport products. This can lead to more efficient use of storage space and optimized logistics operations.

Reduced Accidents: Autonomous robots can prevent accidents and injuries caused by human operators.

Sales and Marketing

Personalized Experience: Robots can be used to provide customized product recommendations based on customers’ personal preferences and automate sales processes.

Improved Customer Service: Robots can be used to answer customer questions and provide technical support. This can increase customer satisfaction and loyalty.

Conclusion

The automotive industry is rapidly transforming with the impact of robots. Robots provide significant benefits to the industry by optimizing production processes, improving product quality and reducing costs. In the future, robots are expected to play an even more important role in the automotive industry. This shift will lead to significant changes in the industry and present new opportunities and challenges. Being ready for these changes and making the necessary investments will ensure that the automotive industry remains competitive in the future.